Magnetic filter rods can be used on their own or can be incorporated into existing equipments, which can be a cost-effective do-it-yourself solution. Magnetic rods ensure product purity and subsequently protect the processing equipment downstream which otherwise may be damaged causing costly repairs.

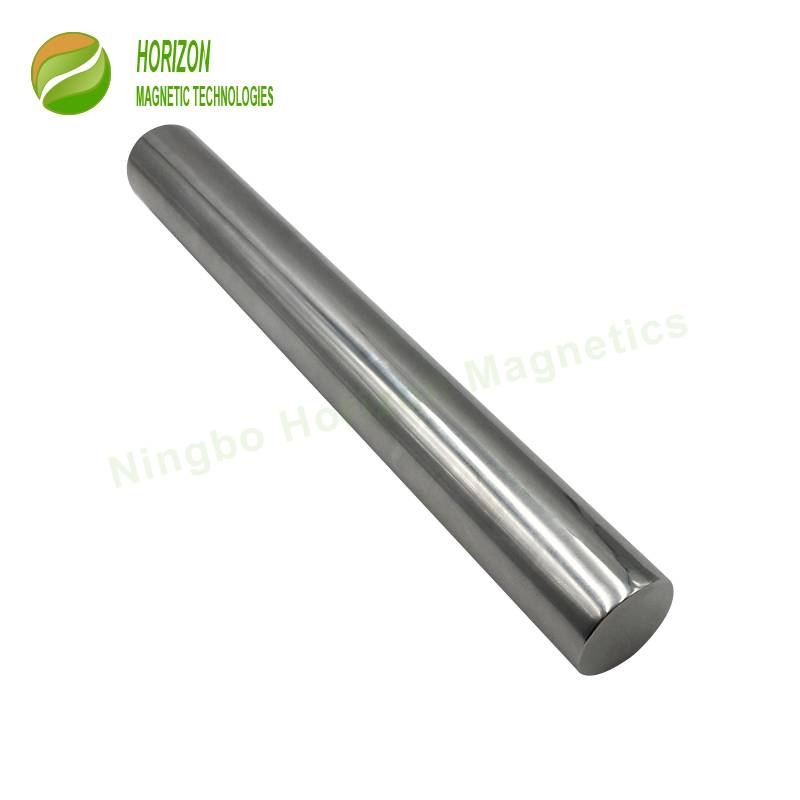

1. Several pieces of strong magnets based on designed magnetic circuit are fully encapsulated within stainless steel tubing to create a strong magnetic field along the side of the tube to attract and retain ferrous material.

2. Majority of the encased magnets are rare earth Neodymium magnetic materials because they generate powerful magnetic field for several options of maximum working temperatures like 80, 100, 120, 150 and 180 degrees Celsius. Samarium Cobalt magnet is available to reach high working temperature to 350 degrees Celsius.

3. Tubes are made from 304 or 316 stainless steel and can be finely polished to meet the requirements of food-grade and pharmaceutical-grade regulations. The magnetic tubes are corrosion resistant and easy to clean.

4. Ends are fully seal welded and end surface design can be selected from pointed end, threaded hole, and stud for easy mounting.

5. For standard applications the tubes are either 25mm or 1" diameter. When installed in a grate arrangement, the gaps between tubes should not be more than 25mm, unless there are multiple rows of tubes. The length could be 50mm, 100mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, 450mm, and 500mm. Square and teardrop shape can be customized.

6. Magnetic strength from 1500-12000 Gauss can be customized. Neodymium magnetic rods could reach over 10000 Gauss and typical peak value over 12000 Gauss on the surface.

1. Food processing

2. Plastics processing

3. Chemical industries

4. Powder processing

5. Glass industries

6. Mining industries