It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for New Fashion Design for China Epoxy Coating Long Block Neodymium Magnet, Welcome mates from all around the world occur to go to, manual and negotiate.

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for China Strongest Magnetic Material, Neodymium Magnet, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We’ve got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

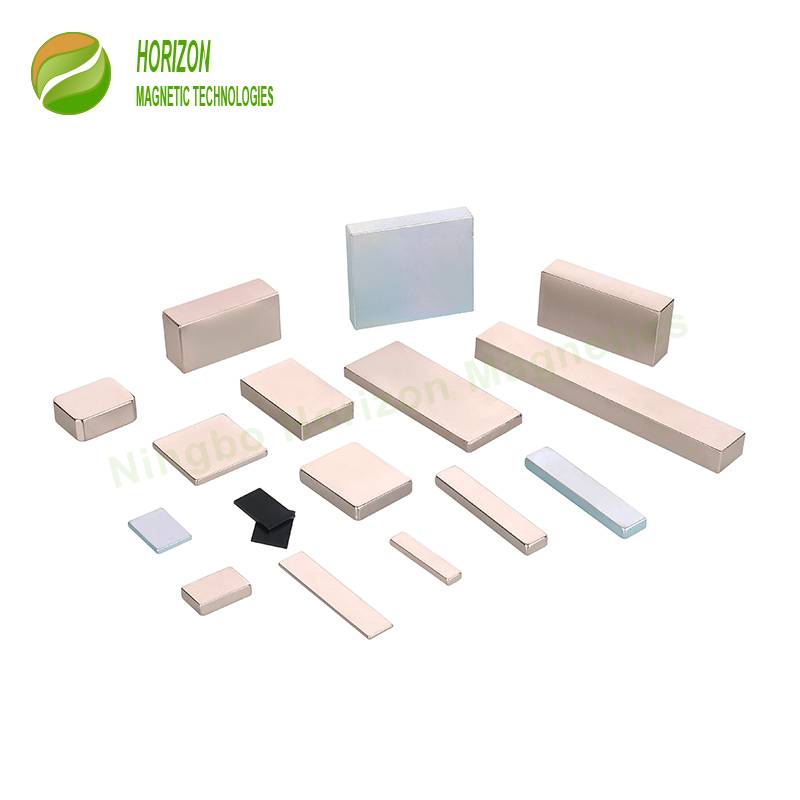

Neodymium block magnet is called as block Neodymium magnet, NdFeB block magnet, or Neodymium rectangular magnet. It is a rectangle shape, and is the most common shape of Neodymium magnet.

Most sizes of Neodymium block magnets are machined from a large magnet block. How is the large Neodymium magnet block produced? In fact, the production process for rare earth Neodymium magnet belongs to powder metallurgy. In this process, a suitable composition of raw materials are pulverized into fine powder, pressed and heated to cause densification via liquid phase sintering, which is the reason that it is often called sintered rare earth magnet. Through melting, jet milling, sintering and aging, a large magnet block or semi-finished Neodymium magnet block is produced with a rough surface and only approximate dimensions.

In order to get the final Neodymium block magnet with smaller and more accurate size, the large magnet block will enter into the machining process, if the magnetic properties are tested OK to meet the requirement. During the machining process, more attention should be paid to size, tolerance, and especially the orientation direction so as to ensure Neodymium block magnet quality.

If the size of the final Neodymium block magnet is big, for example, 100 x 60 x 50 mm, the semi-finished magnet size will be produced similar to the final size, because it’s not easy or economical to produce a semi-finished magnet which can be machined to several or even two final block magnets. The simple grinding process may machine one semi-finished magnet to one final Neodymium block magnet!

Neodymium block magnet has three directions, like length, width and thickness, and generally the Neodymium magnet size is described as L x W x T, such as 30 x 10 x 5 mm. Generally speaking, the shortest one of the three dimensions is the orientation direction. However in many cases the customers might have specific requirement about the orientation, for example for the longest dimension, or multi poles on the same surface…

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for New Fashion Design for China Epoxy Coating Long Block Neodymium Magnet, Welcome mates from all around the world occur to go to, manual and negotiate.

New Fashion Design for China Strongest Magnetic Material, Neodymium Magnet, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We’ve got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.