We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for Manufactur standard China Precast Concrete Magnetic Formwork Shuttering Magnet System Precast Concrete Form For Floor Panel, Welcome to go to our firm and manufacturing facility. You should truly feel no cost to get in touch with us if you need any further assistance.

We insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for China Magnetic Formwork System, U-Profile Shuttering System, We solution have passed through the national skilled certification and been well received in our key industry. Our professional engineering team will often be ready to serve you for consultation and feedback. We have been able to also provide you with no cost samples to meet your needs. Best efforts might be produced to provide you the very best service and solutions. For anyone who is considering our business and solutions, be sure to speak to us by sending us emails or get in touch with us right away. As a way to know our solutions and enterprise. lot more, you’ll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should definitely feel absolutely free to make contact with us for small business and we believe we are going to share the top trading practical experience with all our merchants.

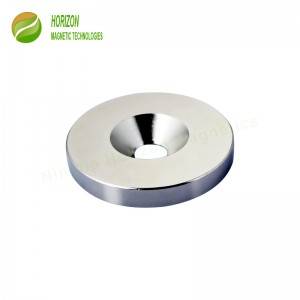

Magnetic shuttering system or magnetic formwork system is used easily, safely and efficiently to profile the formwork to produce many types of large precast concrete elements including popular slabs and solid walls.

This magnetic formwork system consists of a formwork profile with long groove and several powerful Neodymium magnetic systems integrated. The formwork profile is mainly used to shape the mould and encase the powerful but dangerous Neodymium magnet systems. Because the Neodymium magnets are located inside the steel formwork groove, grout or other foreign materials will not cause damage to the formwork system. Moreover, the buttons above the top of the formwork profile makes the magnetic shuttering system easy to activate and deactivate the magnetic attraction force. In the deactivated mode, the lightweight magnetic shuttering system can be easy to lift, move and position on the casting bed or pallet. The shuttering magnet system is not a standard but customized so to suit customers’ requirement about diverse precast concrete elements in length, height, with a chamfer or not, and so on.

1. Easy to move, position and release

2. Suitable for both manual, crane, and robot handling

3. Time saving to place the whole long magnetic side shuttering system directly as a shuttering, while those short shuttering magnets placed individually to support the shuttering

4. Options of chamfers, length, and height available

1. Size: 70mm/Width x 60mm/Height, 500mm, 1000mm, 2000mm or 3000mm/Length or customized

2. Force: 900kgx2, 900kgx3, or customized

3. Max. Operating Temp.: 80C degree or customized

4. Chamfer: two, only or none

1. Customized pulling force, size, chamfer or not, material for formwork profile, etc available

2. Material of magnet: Neodymium magnet with high performance quality, grade and surface treatment to ensure magnetic force strong enough to secure the shuttering profile from sliding during vibrating or stripping process and extend the service time of magnetic shuttering system

3. Material of formwork profile: Several types of materials to meet customers’ specific need. Carbon steel is most cost effective and concentrates the magnetic force the attracting surface and blackening surface treatment creates an oxide film to form a corrosion resistance layer on the steel. Carton steel with polished surface ensures a clean surface for the precast concrete elements. Aluminum is very strong and reduces the risk of bending or deforming in production. Stainless steel is mainly for the robotic handling.

4. Complete supply of precast concrete magnets like formwork magnets, magnetic chamfers, insert magnets, and in-house machining capabilities to produce custom-made magnetic products to meet customers’ one-stop purchaseWe insist over the principle of development of ‘High top quality, Performance, Sincerity and Down-to-earth working approach’ to supply you with exceptional services of processing for Manufactur standard China Precast Concrete Magnetic Formwork Shuttering Magnet System Precast Concrete Form For Floor Panel, Welcome to go to our firm and manufacturing facility. You should truly feel no cost to get in touch with us if you need any further assistance.

Manufactur standard China Magnetic Formwork-System, U-Profile Shuttering System, We solution have passed through the national skilled certification and been well received in our key industry. Our professional engineering team will often be ready to serve you for consultation and feedback. We have been able to also provide you with no cost samples to meet your needs. Best efforts might be produced to provide you the very best service and solutions. For anyone who is considering our business and solutions, be sure to speak to us by sending us emails or get in touch with us right away. As a way to know our solutions and enterprise. lot more, you’ll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should definitely feel absolutely free to make contact with us for small business and we believe we are going to share the top trading practical experience with all our merchants.