Factory directly Laminated Samarium Cobalt Magnet – Samarium Magnet Cylinder – Horizon Detail:

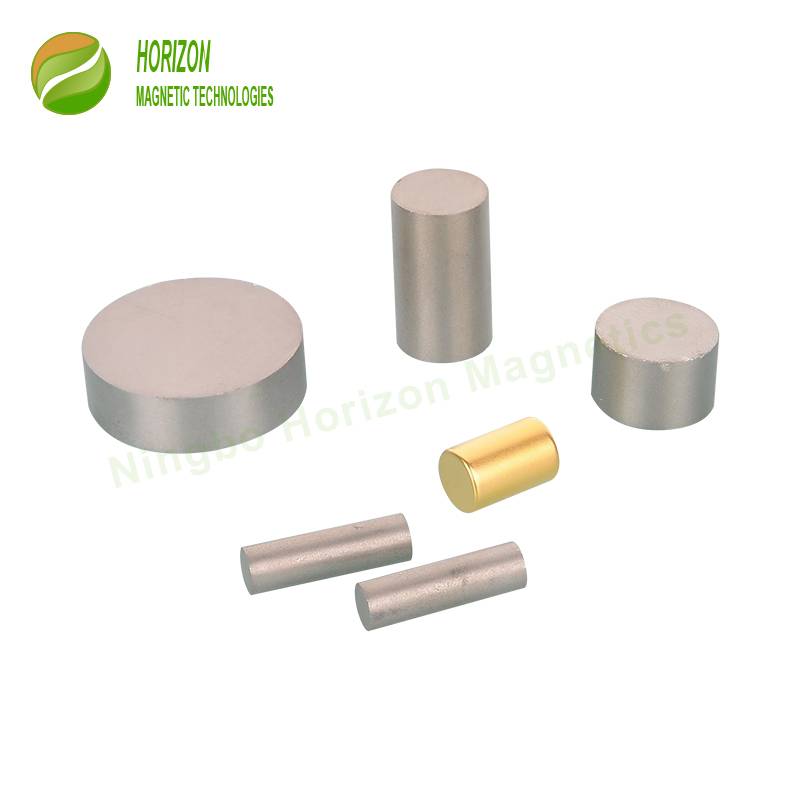

Samarium magnet cylinder or SmCo cylinder magnet describes the round shaped magnet with height larger than diameter. Most of the cylinder SmCo magnets are axially magnetized, and some are magnetized diametrically.

For the axially magnetized SmCo cylinder magnets, sometimes they may be required multi poles magnetized through the length for some specific applications. There are several factors to decide whether the multi pole magnetized SmCo magnet is feasible or not, for example, gap requirement between magnet poles, magnet size, magnetizing fixture, magnet properties, etc. It’s more difficult to magnetize the sintered SmCo magnet to saturation than NdFeB magnet. If the SmCo magnet size is too big, the magnetizer and the magnetizing fixture cannot generate enough magnetizing field to magnetize SmCo magnet to saturation. Normally the thickness of SmCo magnet is required to be lower than 5 mm, and sometimes the Hcj should be controlled around or not exceeding 15kOe. Prior to mass production, the sample of multi-pole magnet must be validated by customers’ comprehensive tests to meet application requirement.

Sometimes, the cylinder SmCo magnets may need plating. Unlike sintered Neodymium magnet easy to oxidize, Samarium Cobalt magnet is good at corrosion resistance due to its specific material composition without Fe or with only around 15% iron. Therefore in most applications, coating is not needed for the SmCo magnet to prevent corrosion. However, in some application fields, SmCo magnet is required to be coated with shiny or pretty Gold or Nickel to reach a perfect appearance.

When customers decide which magnet material is suitable for their application, they also care about the physical properties. Following is physical properties for SmCo magnets:

| Characteristics | Reversible Temperature Coefficient 20-150ºC, α(Br) | Reversible Temperature Coefficient 20-150ºC, β(Hcj) | Coefficient of Thermal Expansion | Thermal Conductivity | Specific Heat | Curie Temperature | Flexural Strength | Density | Hardness, Vickers | Electrical Resistivity |

| Unit | %/ºC | %/ºC | ΔL/L per ºCx10-6 | kcal/mhrºC | cal/gºC | ºC | Mpa | g/cm3 | Hv | μΩ • cm |

| SmCo5 | -0.04 | -0.2 | //6⊥12 | 9.5 | 0.072 | 750 | 150-180 | 8.3 | 450-550 | 50~60 |

| Sm2Co17 | -0.03 | -0.2 | //9⊥11 | 8.5 | 0.068 | 850 | 130-150 | 8.4 | 550-650 | 80~90 |

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Factory directly Laminated Samarium Cobalt Magnet – Samarium Magnet Cylinder – Horizon, The product will supply to all over the world, such as: London, Holland, Cambodia, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!