“Based on domestic market and expand overseas business” is our development strategy for Competitive Price for Customized Sizes Sintered Strong Permanent NdFeB Neodymium Arc Motor Magnet Zn Coating, Constantly for the majority of business enterprise users and traders to supply ideal top quality products and great service. Warmly welcome to join us, let’s innovation with each other, to flying dream.

“Based on domestic market and expand overseas business” is our development strategy for China Magnet and NdFeB, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

Elevator magnet means high performance Neodymium magnet for traction elevator motor application. The elevator motor is the most important component for elevator traction machine, which is the power equipment of the elevator.

High performance Neodymium magnet is the best choice of magnetic material to improve permanent magnet traction machine to ensure the elevator to work with following advantages:

1.High efficiency, energy saving and good dynamic performance of drive system: the permanent magnet synchronous traction machine with multi pole low speed direct drive does not need huge worm gear or worm gear box whose mechanical transmission efficiency is only about 70%.

2.Stable operation, low noise: low speed direct drive, so the bearing noise is low, no fan or worm gear noise.

3.Saving building space: there is no huge reduction gear box and no exciting winding, and high-performance Neodymium permanent magnet material is used. Therefore, the elevator motor is small in size and light in weight, and the machine room can be reduced or not needed.

4.Long service life, safe and reliable: the elevator motor does not need brush and collector ring, so it has long service life, and there is no oil and gas in gear box, so it has less environmental pollution.

5.Less operation and maintenance costs: no brush, no reducer, simple maintenance.

In order to make our elevator magnets exceed the requirement like low noise or vibration and long life time, Horizon Magnetics pay more attention to quality of traction elevator motors in following aspects:

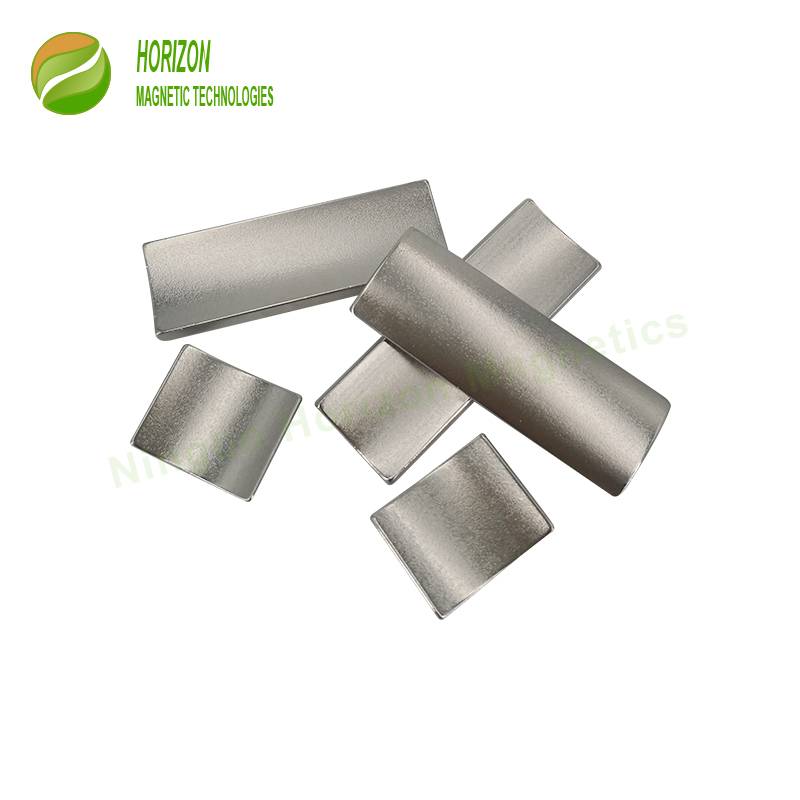

1.Elevator magnets are available in a wide range of shapes such as block, ring, segment, loaf, wedge, etc.

2.Focus on magnets with higher Hci and low reversible temperature coefficients to ensure working with better stability.

3.Control better consistency of magnetic properties between magnets so as to reduce vibration or noise during elevator motor working process.

4.Produce Neodymium elevator magnets with low weight loss and good surface treatment to extend the life time of magnets and then elevator motors.”Based on domestic market and expand overseas business” is our development strategy for Competitive Price for Customized Sizes Sintered Strong Permanent NdFeB Neodymium Arc Motor Magnet Zn Coating, Constantly for the majority of business enterprise users and traders to supply ideal top quality products and great service. Warmly welcome to join us, let’s innovation with each other, to flying dream.

Competitive Price for China Magnet and NdFeB, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.