With the vigorous development of the electronic industry, the position detection of some structural components slowly changes from the original contact measurement to the non-contact measurement through Hall position sensor and magnet. How can we choose a suitable magnet according to our products and structure? Here we do some simple analysis.

First, we need to determine the magnet material. At present, samarium cobalt magnet and neodymium iron boron are widely used in hall position sensor. The main difference between the two magnets is that based on the same volume NdFeB magnet are stronger than samarium cobalt magnets; the thermal excursion of samarium cobalt is smaller than that of Nd-Fe-B; the oxidation resistance of samarium cobalt is stronger than that of Nd-Fe-B, but generally there is a coating on the outside of the magnet, which can solve the problem of oxidation; the samarium cobalt magnet has better temperature resistance than NdFeB magnet, but temperature resistance value for both magnet materials can reach more than 200 ℃. Therefore, when selecting the type of magnet, we should evaluate it in combination with cost performance, working temperature and working environment. In general, NdFeB may be used more, mainly because it has the best magnetic field characteristics. However, when working in a wide temperature range, it is recommended to choose samarium cobalt magnet because of its small thermal drift.

In addition, we need to determine some basic parameters of the magnet. According to the test position information and the moving direction of the object, we determine whether the magnetization direction of the magnet is diametrical or axial. In addition, it is determined whether to select a square magnet or a cylinder magnet according to the installation structure. Of course, sometimes we need to customize the shape of the magnet according to the structure. There is another factor of requirement about magnet flux, which has always been our concern in magnet selection. In fact, we need to analyze it in the following two aspects:

1. The magnetic field strength induced by the hall position sensor itself and the induced magnetic field range in each direction will be clearly marked in the sensor data book.

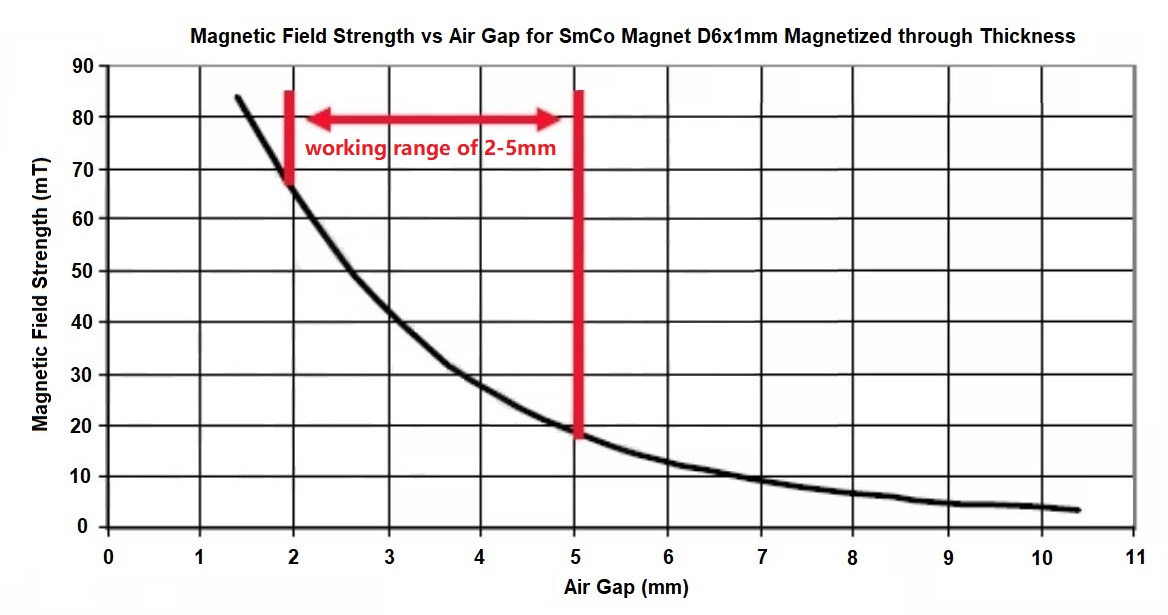

2. The distance between the magnet and the sensor itself is generally determined by the product structure. According to the above two aspects and the magnetic field change curve in the figure below as an example, we can determine the magnetic field strength of the required magnet.

Finally, we must need to understand that it does not mean that as long as the magnetic field falling on the range requirements of the sensor, the magnet can be as far away from the sensor. Although the sensor itself has calibration function, we need to understand that when the magnet is too far from the sensor, the distribution of the magnetic field itself is difficult to ensure linearity or close to linearity. This means that with the change of position and the nonlinear distribution of the magnetic field itself, the sensor measurement will become complex and the calibration will become very complex, so that the product does not have reducibility.

The above is just a simple analysis of magnet selection in Hall sensor applications. We hope it will be helpful to you. If you have other questions during the development process, please contact us, Ningbo Horizon Magnetics. We can make further communication and provide you with technical support.

Post time: Aug-12-2021