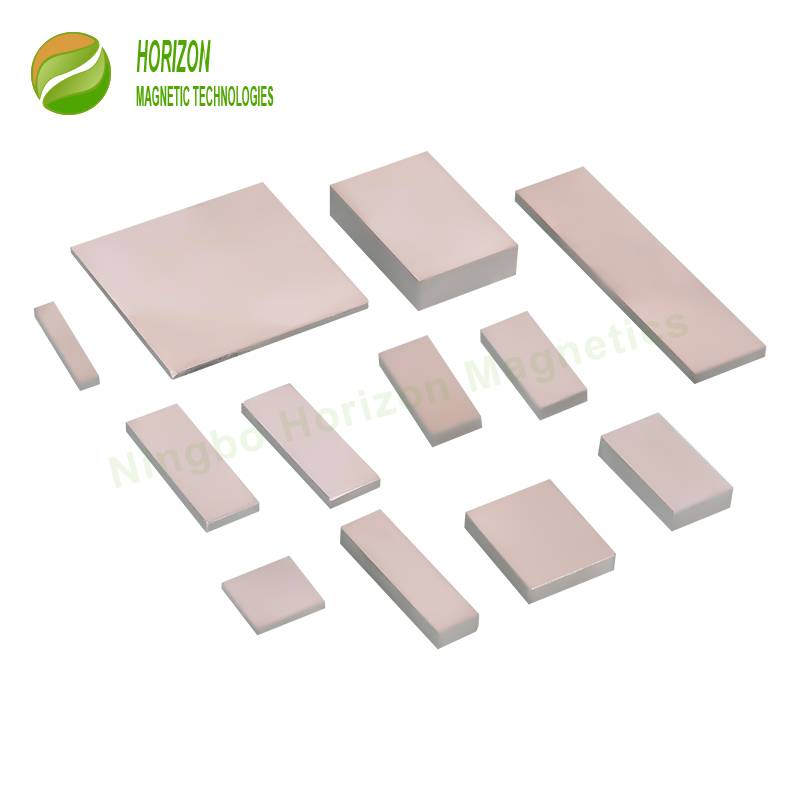

Hot Selling for Samarium Cobalt Segment Magnet - Rectangle Samarium Cobalt Magnet – Horizon Detail:

Rectangle Samarium Cobalt magnet, Samarium Cobalt magnet block or SmCo rectangular magnet is a common type of block shaped SmCo magnet. The block SmCo magnet has a widely application in high quality electric motors, sensors, ignition coils, magnetic pump couplings, etc, due to its specific features as follows:

1.High magnetic values with Br high to 11.7 kG (1.17 T) and (BH)max high to 35 MGOe (275 kJ/m3)

2.High working temperature with maximum working temperature high to 250 ºC ~ 350 ºC

3.Outstanding thermal stability with reversible temperature coefficient low to -0.03 %/ºC for Br and -0.2%/ºC for Hcj

4.Excellent corrosion resistance and then no surface treatment required, especially in the high corrosion working environment

5.Excellent demagnetization resistance because of Hcj higher than 25 kOe (1990 kA/m)

Generally several pieces of rectangle SmCo magnets are sliced via the inner circle cutting from a rectangular magnet block directly. If it is a thin block SmCo magnet and the quantity is large, the multi-wire cutting machine is used to save machining cost, increase the machining efficiency, reduce magnet material waste so as to ensure better price for customers. If the dimension of one or two directions is large, for example >60 mm, it should need grinding and EDM (electrical discharge machining), due to the limits of the inner circle slicing machine. If all three directions are too large, only grinding is needed.

There is some limit about size requirement for rectangle SmCo magnets with following specification:

Normal size range: L (Length): 1 ~ 160 mm, W (Width): 0.4 ~ 90 mm, T (Thickness): 0.4 ~ 100 mm

Maximum size: Rectangular: L160 x W60 x T50 mm, Square: L90 x W90 x T60 mm

Minimum size: L1 x W1 x T0.4 mm

Orientation direction size: Lower than 80 mm

Tolerance: Generally +/-0.1 mm, Particularly +/-0.03 mm

If customers prefer the dimension of one direction to be large, the other two directions have to be narrowed accordingly. If two directions are large, too thin thickness is not allowed, because SmCo magnet is too brittle and it’s easy to fracture during machining and assembling.

Product detail pictures:

Related Product Guide:

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We're ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for Hot Selling for Samarium Cobalt Segment Magnet - Rectangle Samarium Cobalt Magnet – Horizon, The product will supply to all over the world, such as: Comoros, Israel, Bahamas, If you are interested in any of our products and solutions or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.