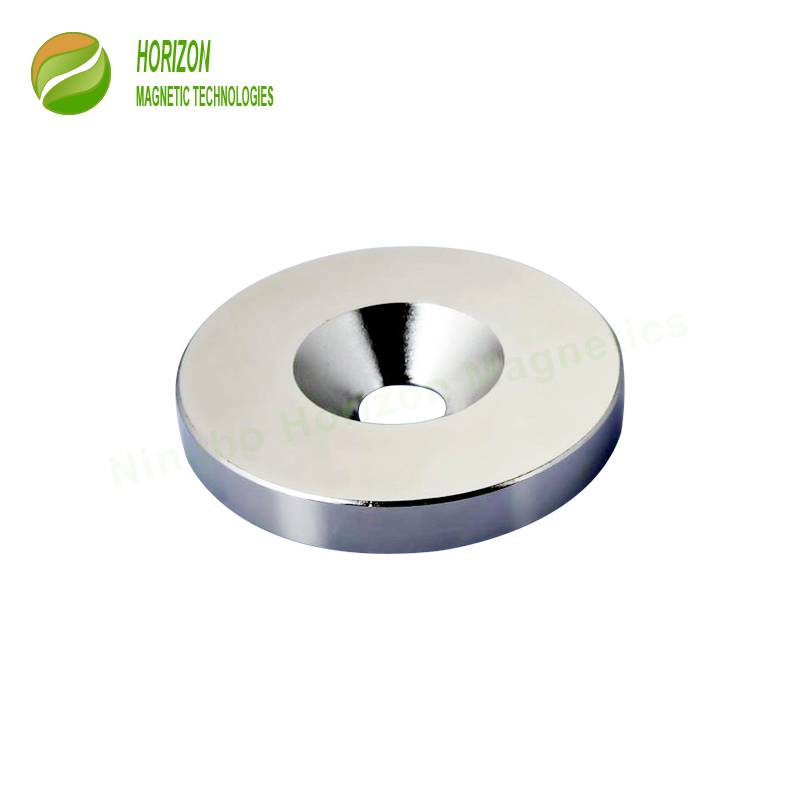

Factory For Laminated Neodymium Magnet - NdFeB Countersunk Magnet – Horizon Detail:

NdFeB countersunk magnet is also called Neodymium countersunk magnet, countersunk permanent rare earth Neodymium magnet or countersunk magnet. The countersunk hole structure enables its easy use in the assembling process.

When you receive the NdFeB magnets, you must need to use them in your products. How do you assemble the magnets to your products? Sometimes, you may glue the magnets to your products; you may insert the magnets to the slots machined specially in your products; you may fix the magnets to your products via epoxy; you may use countersunk screws to bolt the magnets to your products tightly……

While the countersunk magnet and countersunk screw is easy to meet your special assembling requirement. Screw plays an important role of connecting two or more objects, which is indispensable in daily life or industrial manufacturing. Generally, the head of the screw will protrude on the upper part of the connected object surface for example Neodymium magnet, and then the surface will lose flatness. The head of the countersunk screw is a 90 degree cone, which can be sunk under the surface of magnets into the countersunk hole of the NdFeB magnet to make the connecting surface smooth. For hard objects like Neodymium magnet, countersunk holes should be drilled at the corresponding position of the countersunk head. In short, the countersunk head is the head of the screw, which can keep the surface smooth after installation. In order to facilitate the tightening of the screws into the countersunk magnet, similar to the common wood screws, there are tightening grooves on the head, such as slot, cross shaped, hexagon, star, etc.

Sometimes customers might find some countersunk magnets with bigger angle from other countersunk magnet suppliers. The main problem might come from the machining process. The countersunk hole is 90 ° cone angle, but the top angle of the newly purchased drill is 118 ° – 120 ° generally. Some workers who lack training do not know the angle difference at all, and often use a 120 ° drill to ream the hole directly.

1. Genuine NdFeB magnet raw materials to ensure magnet quality and extend lifetime

2. Countersunk holes in the magnet with excellent shape, surface and position

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Factory For Laminated Neodymium Magnet - NdFeB Countersunk Magnet – Horizon, The product will supply to all over the world, such as: Montpellier, Washington, Burundi, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.